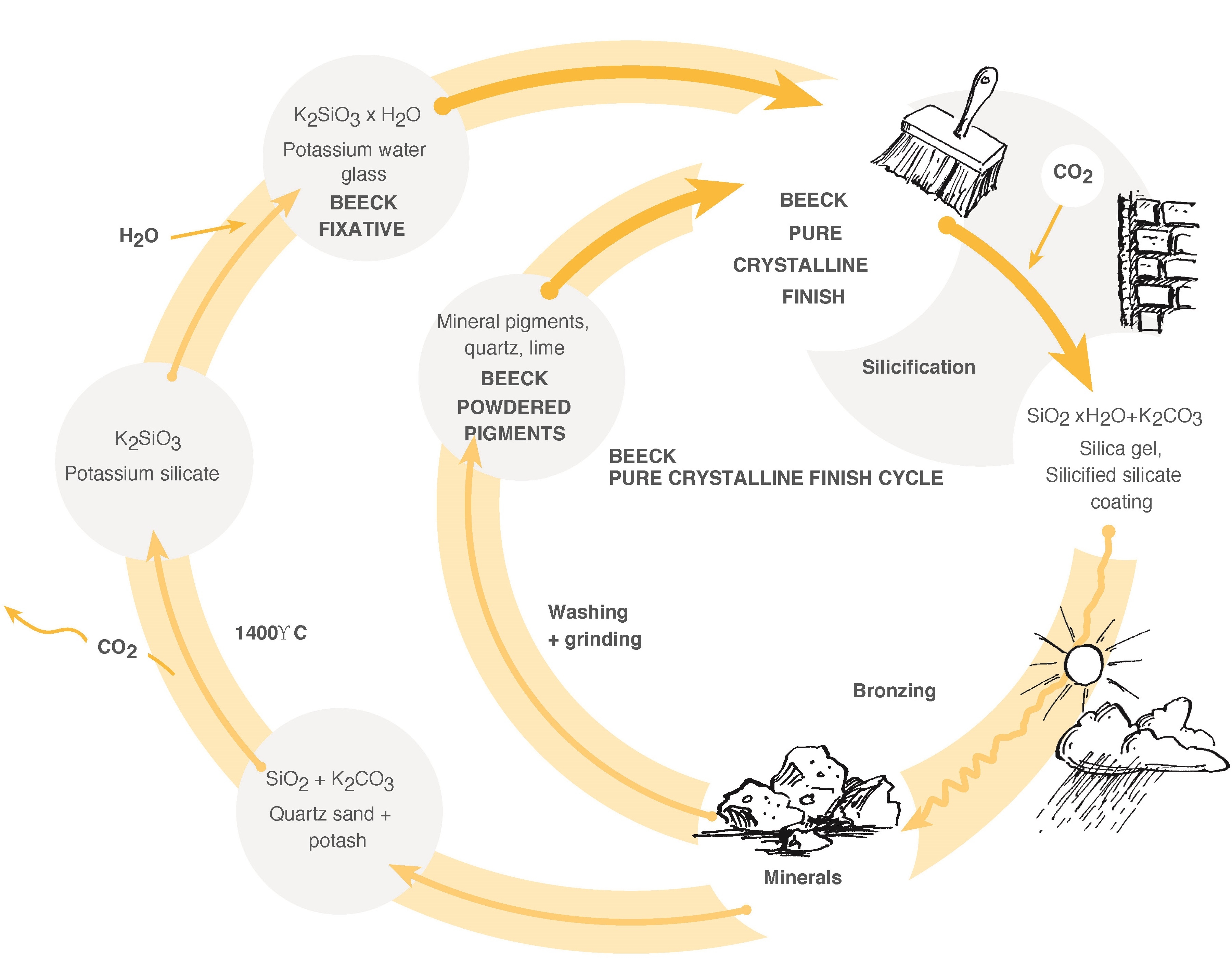

The Silification Cycle

Have you ever wondered how our Beecks breathable mineral based paints are so effective? Being able to maintain brilliantly clean facades, even after decades – free from dirt deposits and algae growth.

This is made possible by the process of silicification, the petrification of liquid potassium water glass to form solid, extremely resistant silicates that are stable when exposed to weathering. It also ‘sets’ to become part of the building giving durability above and beyond most other forms of ecological paints.This process has been known of since the beginnings of silicate paint technology, well over 100 years ago, so it is well established and the advantages understood. However, the transfer of this principle to the silicate emulsion paints is new. It is a cycle, see below, much like the lime cycle, and so has minimal environmental impact.

The intensive silicification of coating and substrate and therefore enables coatings with unsurpassed lives, even on exposed, weathered façades.

This is in contrast to the film formation of emulsion, silicone resin and passive silicate paints usually used in practice. With these, a physically drying synthetic resin glues the surface of the building material with the pigments and fillers. A more or less porous but also vapour-tight coating firm is formed, depending on the formulation and binder content.

All film-forming coatings tend to become brittle, form cracks and then flake off when exposed to weathering – a sign of their poor keying with the substrate. Commercially available passive silicate paints are suitable, for example, as an interior silicate coating on woodchip wallpapers or gypsum board. In the exposed, weathered façade area on the other hand they display hardly any increased durability compared to standard emulsion coatings.

The capillary-active coatings have ideal open porosity, and are therefore extremely valuable in building physics terms. Thanks to silicification they form an inseparable mineral unit with the render, do not tend to flake and also do not form a vapour-tight, high-tension rind in when renovated. This open porosity also ensures a balanced, healthy living room climate. The high alkalinity of the coatings has a mould resistant and bactericidal effect. Free from solvents, plasticisers, biocides and preservatives they fulfil the strictest room air hygiene requirements.

These pure mineral paints are not only suitable for traditional building materials (maintain breathability) but also on composite materials and lightweight building components. A wide range of primers opens up the use on substrates with weak silicification which means they are suitable for most applications.