Choosing a Lime

It is important for the well-being of the building that the most appropriate lime product is chosen. Every situation needs to be carefully assessed e.g. in terms of:

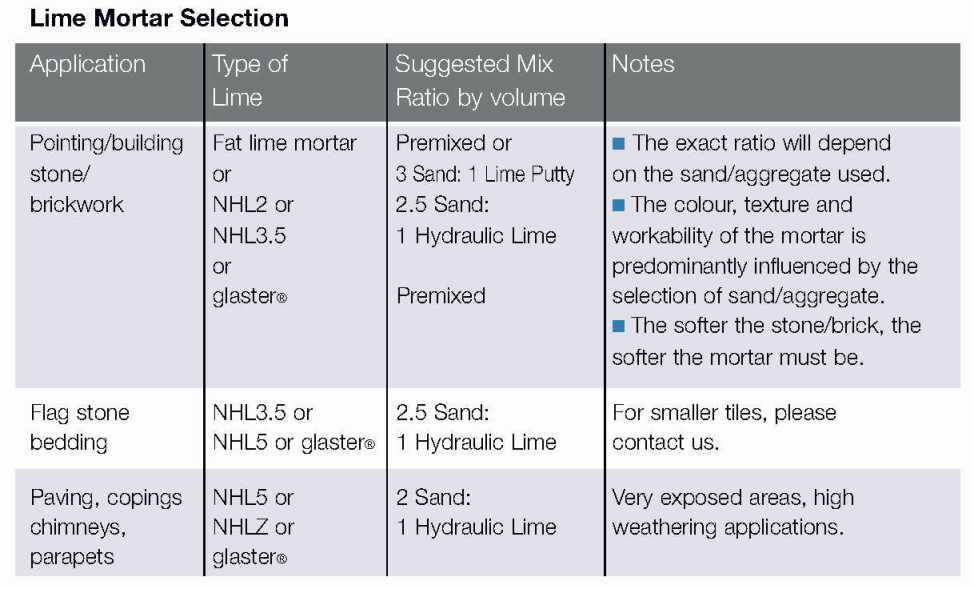

- Softness, porosity and capillarity of the stone, brick etc – this should be a major factor in selection. The mortar should always be ‘softer’ than the stone/ brick, see table below. *It is important not to choose lime simply based on its compressive strength, mostly this is not helpful, even the ‘softest’ stones will have a higher compressive strength than strong mortars it is the capillarity and porosity which are important.

- The environmental conditions – where the environment is very wet e.g. sea defence walls, canal walls, cellars, copings, pavings; a hydraulic lime is more appropriate because of its ability to set in harsher conditions, see table below.

- The existing materials – repairing like-with-like – this will usually provide the most satisfactory solution both aesthetically and technically, however it should not be done without considering the performance of the original materials.

- The time of year – the ideal time to do fat lime work, particularly external work, is during the spring and early summer, lime work should never be done when the temperature is likely to fall below 5°C before carbonation has taken place, WORK SHOULD BE SCHEDULED TO TAKE THIS INTO ACCOUNT. If work cannot be rescheduled to another time of the year consideration should be given to adding a pozzolan to a fat lime (e.g. PFA, GGBFS, brick dust, calcined clay) to speed up the set or switch to using a natural hydraulic lime. Appropriate protection is vital.

- The available time – occasionally work is programmed without enough time to support the use of the materials specified, rapid builds necessitate rapid sets, therefore, adding a pozzolan to a fat lime or using a natural hydraulic lime instead could be considered (if work can’t be reprogrammed!), but for best results application during autumn and winter months should be avoided.

Occasionally, the choice still seems to be based on the availability of skills (or lack of them) and this does mean that often in these cases that the stronger hydraulic limes or even cement are introduced into buildings where they have no place and will, in the long term, almost certainly cause damp problems and damage the very fabric of the building. The next sections look at the various lime-based products in more detail and set out some ‘golden rules’ for successful results.

Before beginning to use any lime product, it should be understood that eyes and skin should be protected at all times.